Ensuring the safety and security of toys through several strict inspections

To supply safe and secure toys, Bandai and Bandai Spirits are committed to quality assurance based on their own unique quality standards. Below, let us take a look at how toy inspections are carried out.

Supplying safe, worry-free toys by ensuring higher quality and safety

Safety and security are essential aspects of toys. We must never allow children to experience danger with toys that are meant to be fun to play with. Bandai and Bandai Spirits therefore believe that toy manufacturers have a duty to achieve high levels of quality and safety. We are committed to creating safe toys that children can play with worry-free.

Around 260 inspections are conducted before a toy reaches the store shelf

All toys made by Bandai and Bandai Spirits undergo extensive quality inspections before reaching the store shelf. In addition to the safe toy standards (ST standards) set by the Japan Toy Association, Bandai has established its own quality standards covering approximately 260 items, which are broadly divided into the three categories of safety, function, and labeling. Depending on the product specifications, we extract relevant items from these standards and conduct inspections before bringing the product to market.

We carry out the following three stages of inspections.

1. New-product inspection

New-product inspections confirm whether prototypes have been produced in accordance with the quality standards established by Bandai. Mass production of a new product cannot begin unless it passes this inspection.

2. Pre-shipment inspection

Pre-shipment inspections are conducted by factories entrusted with mass production and ascertain whether mass-produced toys match the specifications of the prototype that passed the new-product inspection.

3. Acceptance inspection

Product-acceptance inspections are conducted after pre-shipment inspections conducted at factories. Under these inspections, Bandai checks whether mass-produced toys match the specifications of the prototype that passed the new-product inspection. Additionally, by systemizing quality control documents and managing them appropriately, we are able to improve safety and respond quickly to any inquiries that may arise.

Example of quality inspection for achieving safety and security

Sharp-point test

A test to check whether there is a risk of injury due to dangerous points on hidden parts

Product-drop test

A test to check whether any dangerous parts that could lead to injury are created by the impact of being dropped

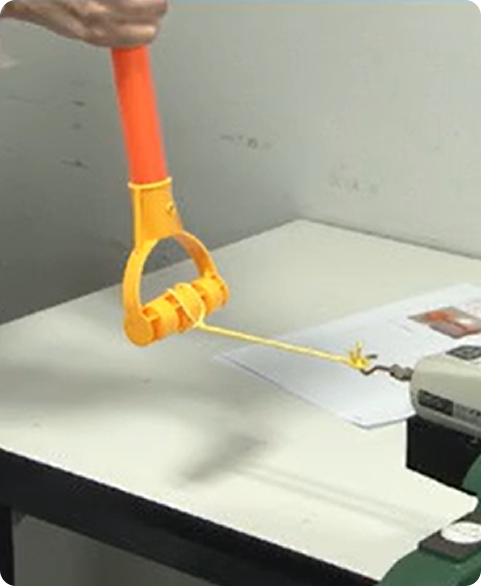

Bend and pull test

A test to check whether any dangerous parts or small parts are generated by bending or pulling the protruding parts or attached parts

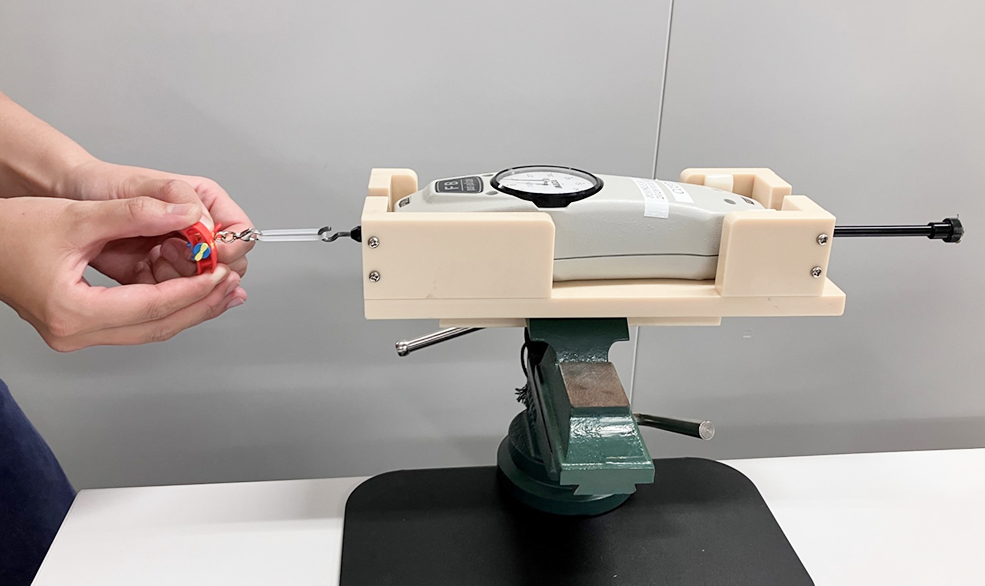

Tape test

A test to check whether paint, printing, coloring, and plating are firmly attached and their strength

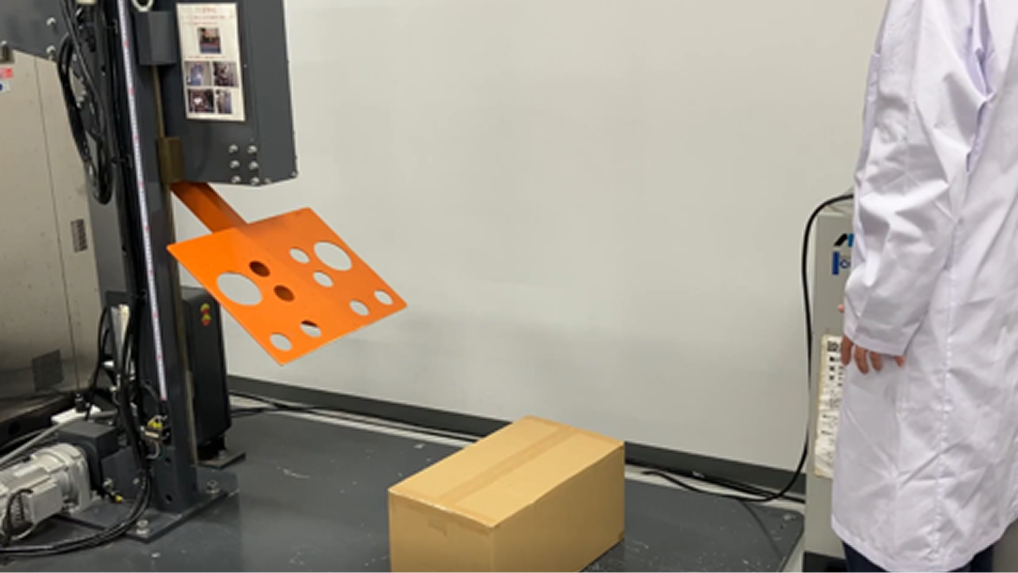

Carton fall test

A test to confirm whether the product is protected from impacts when loading and unloading cartons containing a product

Continuing our pursuit of safety and security to bring fun toys to fans around the world

Quality assurance is meaningless if a process is created but not carried out properly. Therefore, checking whether quality assurance is being carried out properly is an important step for maintaining safety and security.

At all overseas final packaging plants that manufacture products for the Japanese market, both Bandai and Bandai Spirits regularly conduct Bandai Factory Audits (BFAs), which integrate quality audits and certificate of conformity (CoC) audits, as well as audits based on third-party CoC standards.

Since we sell many of our products globally, in addition to the standards for toys set in each region of the world, we have established approximately 200 original quality standards, thereby creating a system that enables us to deliver safe and reliable products to overseas customers. Moving forward, we will continue to heighten our conformance to regional standards.

To continue ensuring the safety and security of its toys, the Bandai Namco Group will continue to strengthen quality control by reviewing safety standards in line with changes in the social environment and establishing new standards.