Sustainable Use of Resources

and Raw Materials

Companies are responsible for helping to achieve a sustainable, recycling-oriented society. Today, the world is making greater efforts to reduce waste by reviewing raw materials and reining in the use of plastics that could harm marine and other ecosystems. The Bandai Namco Group stands committed to reducing and controlling its waste emissions, in addition to using natural raw materials more efficiently and to a lesser extent.

Initiatives for Waste Reduction and Recycling

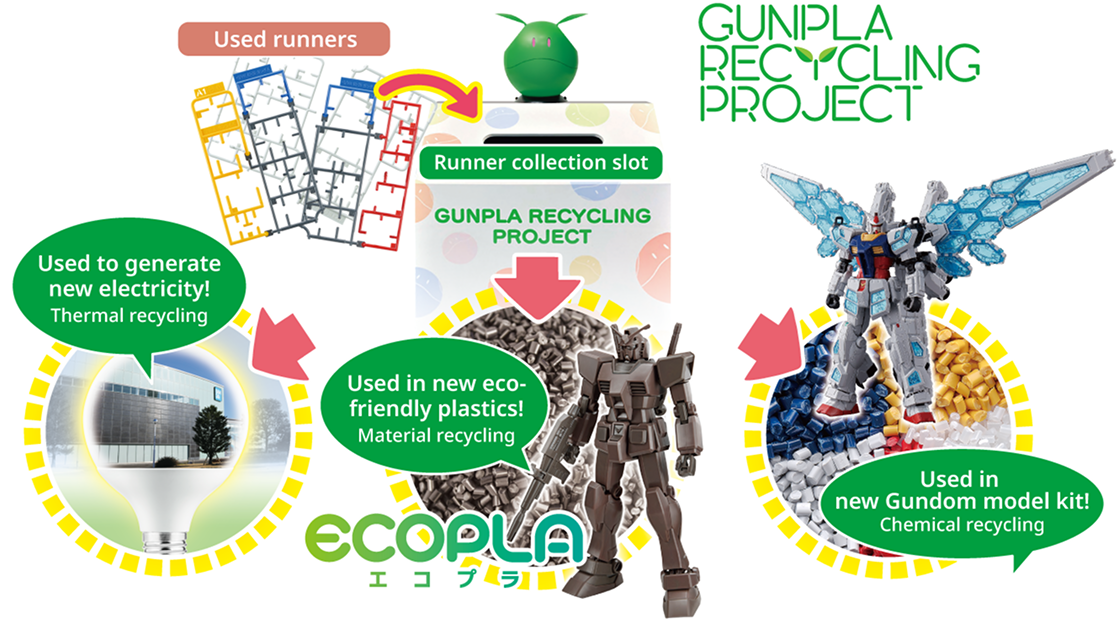

Contribute to a recycling-oriented society through the Gunpla Recycling Project

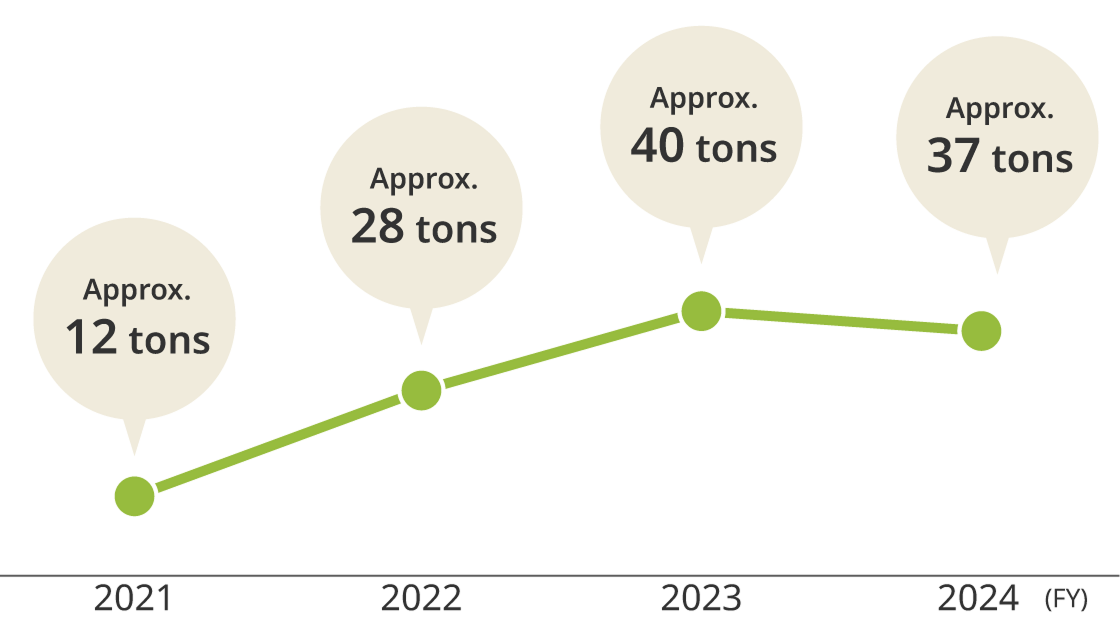

Under the Gunpla Recycling Project, which started in April 2021, we collect runners (part of the model kits framework) from model kits in the Gundam series and reuse them in new model kits through the use of a cutting-edge chemical recycling process. By doing so, we aim to create a recycling-oriented society together with Gundam fans. The runners collected through the project are transported to the Bandai Hobby Center, a model kits manufacturing plant of Bandai Spirits.

A portion of these runners is used as a material for verification testing targeting the realization of chemical recycling, and the rest is reused through material recycling or thermal recycling, together with plastics created through the manufacturing process at the Bandai Hobby Center.

In fiscal 2024, we collected approximately 37 tons of runners.

© SOTSU・SUNRISE

Read more

Promoting the recycling of Gashapon® capsules

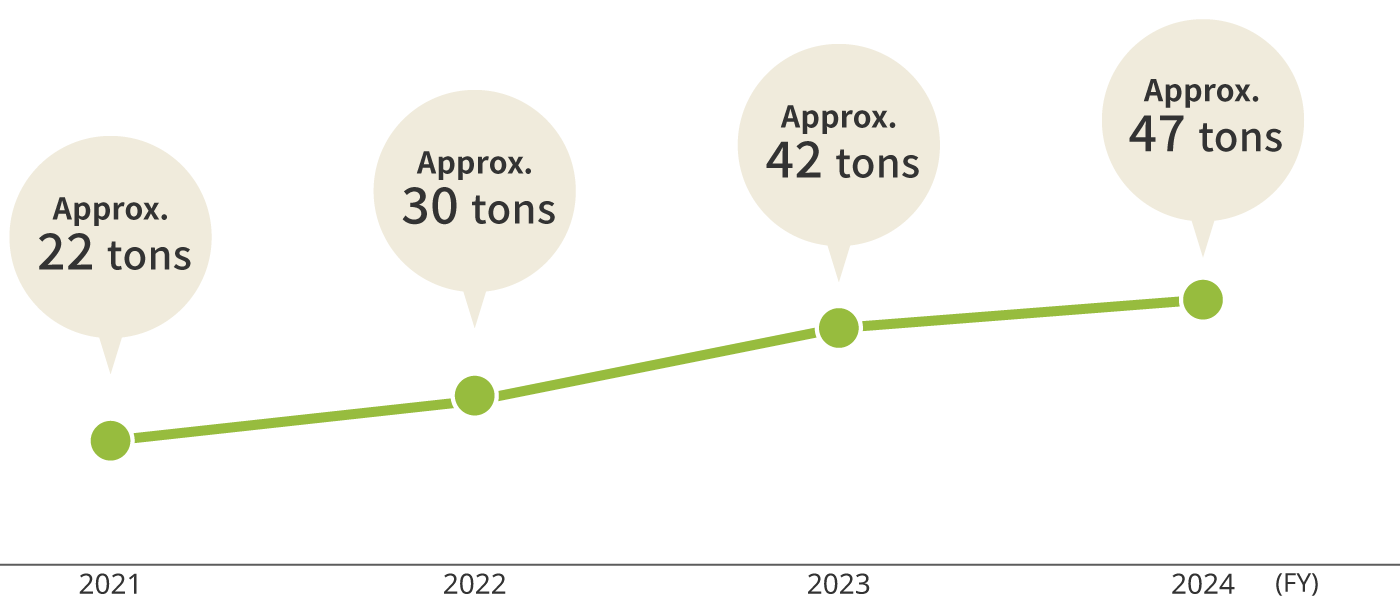

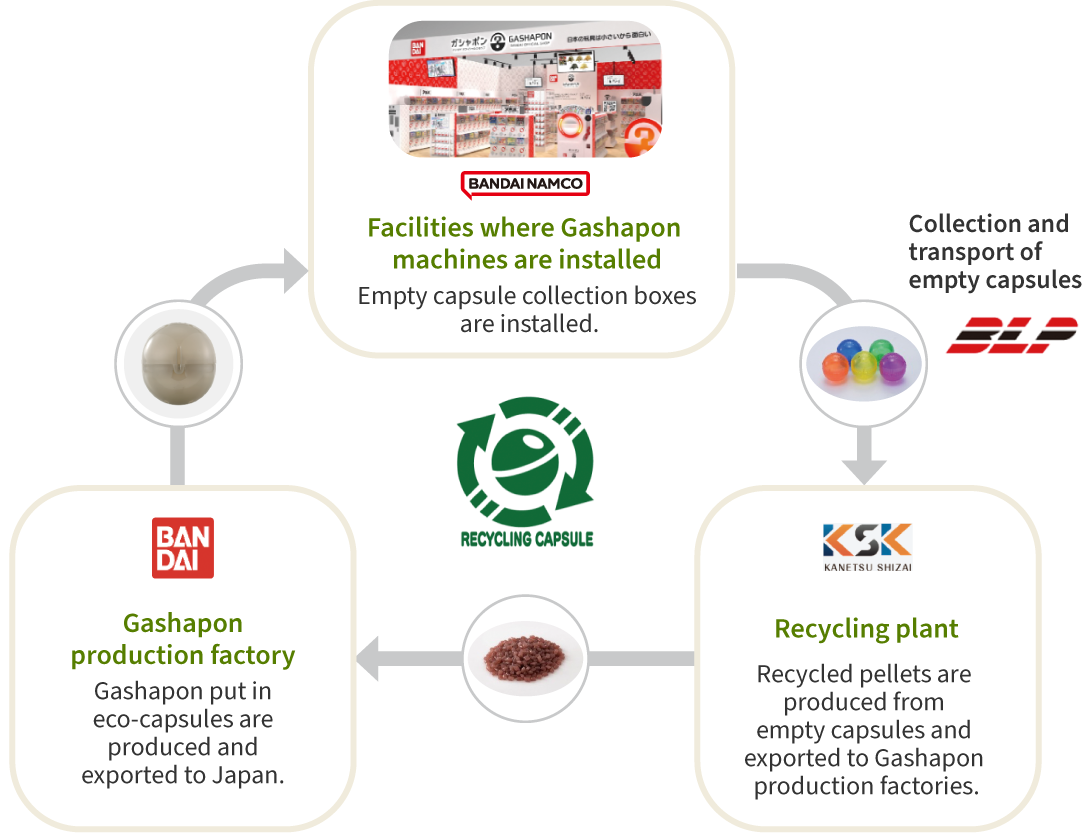

The Bandai Namco Group has collected and recycled Gashapon capsules since 2006. In 2021, Bandai, Bandai Namco Amusement, and Bandai Logipal jointly started Gashapon Capsule Recycling, an initiative to further expand these recycling efforts. (Amount collected in fiscal 2024: approximately 47 tons)

The collected empty capsules are turned into pellets (recycled pellets), which are the raw materials for capsules, and then they are mixed with ordinary pellets (virgin pellets) to form the capsules. At present, recycled pellets account for about 40% of new capsules.

In addition, we have set up Gasha Point Stations, empty capsule collection boxes at Gashapon Department Stores and Gashapon Bandai Official Shops. This makes the empty capsule collection an enjoyable experience for customers.

In fiscal 2025, we held Gashapon Sustainable Action—Capsule Recycling Promotion Month starting on June 5th, Environment Day.

To coincide with Environment Month in June, we held a campaign at official Gashapon Bandai shops nationwide to encourage people to have fun recycling capsules in stores. This included a greeting event featuring Kuchipatchi (a popular Tamagotchi character), Bandai’s environmental ambassador, as well as an event linked to the Namco Points app, where customers could place three empty capsules in a capsule collection machine and receive a Kuchipatchi paper file (made from FSC®-certified paper).

Through its original capsule toy brand, Gashapon, Bandai engages in a variety of sustainable activities.

Initiatives to reduce food waste

All Bandai Namco Group companies are making efforts to address the social issues of leftover food and food loss.

Bandai

Bandai has conducted repeated verification testing on its confectionery products, including the Tsuri Gummies series and Charapaki series. Five years of this research has helped extend the best-before dates of these products. Additionally, as a result of various initiatives, such as reducing product and raw material waste in the production process, we achieved a 52% reduction in food loss in fiscal 2024 compared to fiscal 2021.

Artpresto

The leftovers from the confectionery Artpresto sells are effectively used as animal feed, reducing waste by approximately four tons per year.

© BANDAI

Bandai Namco Studios Singapore

In partnership with The Food Bank Singapore, employees of Bandai Namco Studios Singapore donated non-perishable food items and delivered them to those in need.

This not only helps reduce waste but also contributes to the local community by supporting people in need of food and other daily necessities.

Effectively utilizing water resources at our domestic and overseas locations

The Bandai Namco Group is working to make effective use of water resources at each of its business locations in Japan and overseas.

Bandai Spirits

The Bandai Hobby Center, the plastic model production plant of Bandai Spirits—which plans, manufactures, and sells Gunpla® and other products—has a two-ton rainwater storage tank under both the existing and newly constructed buildings. The stored rainwater and well water are filtered through a treatment system and supplied to flush toilets in the plant as well as used to water the plant’s landscaping. This ensures that some 2,100 tons of rainwater is reused every year.

Bandai Namco Music Live

Bandai Namco Music Live is involved in planning and producing music content, discovering and nurturing artists, and producing live events. We have installed rainwater storage facilities in our offices in an effort to make effective use of water resources.

Bandai Namco Holdings USA

In the United States, Bandai Namco Holdings USA’s headquarters in Irvine, California, has installed water-saving equipment. As a result, the office has been certified as a water-saving facility by the Irvine Ranch Water District*.

*A public agency that manages water and sewerage in California.

Ensure live events are environmentally considerate

Bandai Namco Entertainment

At THE IDOLM@STER event venues, Bandai Namco Entertainment works with Lumica Corporation, a manufacturer and retailer of glow sticks and concert light wands, to sell and collect the new, easily recyclable “Lumica Daisenko Kiwami Re.” This light wand is environmentally friendly and sustainable, and can be recycled or reused by separating each part after use. Through this activity, which allows event goers to participate in environmental efforts while having fun, we collected approximately 1,223 kg at 10 locations nationwide in fiscal 2024.

Bandai Namco Music Live

Bandai Namco Music Live uses LEDs in many places to illuminate live events to save energy.

Re:vale LIVE GATE “Re:flect U”

Main Arena of Musashino Forest Sport Plaza

Strengthen activities to separate waste components and promote recycling

Bandai Namco Technica, a supplier of arcade games, has been promoting recycling initiatives since 2010 to ensure that limited resources are still available in the future. We carefully separate metals, printed circuit boards (PCBs), wiring, and HDDs that are replaced during the course of maintenance and other work. In fiscal 2024, we recycled approximately 5.6 tons of materials and components.

Initiatives for recycling waste plastics

Artpresto has been working to recycle waste plastics from its plants since 2017. The company outsources the recycling of packaging material waste from its production lines to its partner RPF* production plants.

RPF is a high-calorie solid fuel made primarily from recovered paper and waste plastics that are difficult to conduct material recycling. It effectively reduces greenhouse gas (CO2) emissions by one-third compared to the same amount of heat obtained when burning coal. RPF conversion of waste plastics is stipulated in Japan’s new plastics law as an energy recovery method. In fiscal 2024, Artpresto recycled approximately 105 tons of waste plastics as RPF.

*Refuse derived paper and plastics densified fuel. RPF is an alternative to fossil fuels such as coal, coke, and heavy oil, used for high-efficiency heating by major paper manufacturers (power generation and manufacturing processes), limestone companies, and biomass power plants (assisted combustion).

Note: Photo credit by EcoMining Co., Ltd.

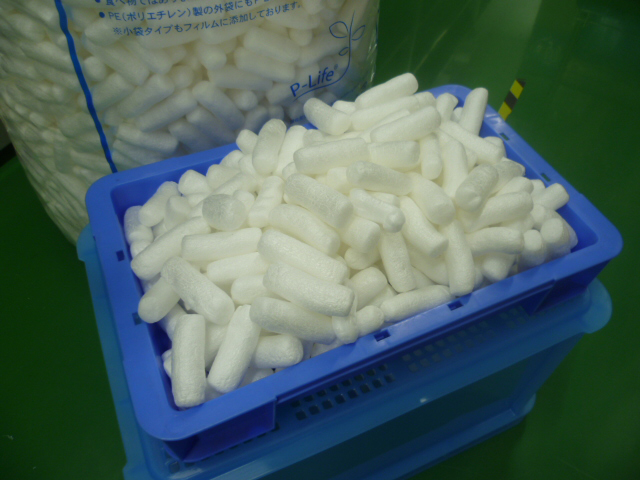

Alternative cushioning materials

Bandai Namco Technica has been using environmentally friendly materials for more than 10 years. These materials are used to make packaging materials (more than 8 cubic meters per year) for shipping amusement machines. Specifically, the use of buffer materials made primarily from processed rice has resulted in zero emissions of toxic gases during incineration. This buffer material is also characterized by its low combustion calorie content and low burden on incinerators. In addition, P-Life* is added to prevent the polypropylene (PP) contained in the product from being released as microplastics.

*An additive that transforms non-degradable plastics such as PE and PP into oxidized biodegradable plastics.

Reducing the usage of prize bags

Bandai Namco Amusement has installed roughly 300 “Fukulocker” (prize bag vending machine) units, provided by Group company Bandai Namco Technica, at amusement facilities “Namco” nationwide to standardize customer service and reduce the usage of prize bags.

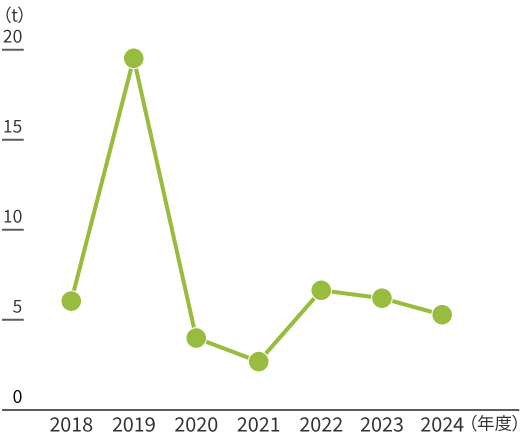

By charging money for these prize bags, we have been successfully curtailing their provision beyond necessity, reducing the volume of prize bags used in fiscal 2024 by nearly 57.38 tons (about 3.97 million bags) compared with fiscal 2019.

Card Pack Recycling Project

Bandai, which carries trading card game cards, is running a project to collect opened packs and repurpose them into new products.

Starting in January 2024, collection boxes were set up at ONE PIECE card game official shops (15 stores as of January 2025) and event venues nationwide, marking the start of collection. Approximately 363 kg of card packs were collected over the course of the year. The collected card packs are remade into card cases, essential for trading card games, and distributed to customers at events and other occasions. These card cases are made using approximately 45% recycled plastic, including opened card packs.

Read more

Accredited as Water Cycle ACTIVE Company

The Secretariat of the Headquarters for Water Cycle Policy Secretariat of the Cabinet Secretariat launched the Water Cycle Company Registration and Certification System. The system proactively registers and accredits companies interested in initiatives to aid water recycling or engaged in those initiatives, with the aim of further promoting water recycling initiatives by companies.

The Bandai Namco Group was accredited as a Water Cycle ACTIVE Company in fiscal 2024.

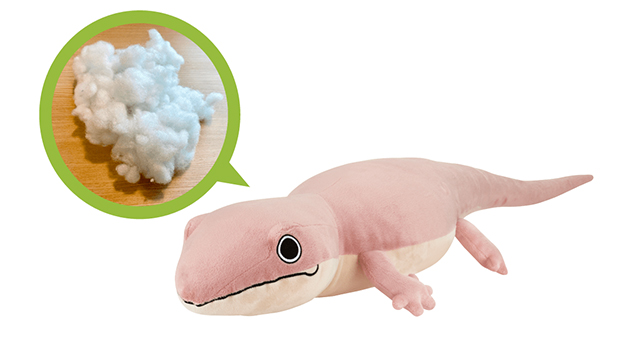

Actively utilizing recycled stuffing in products

Stuffed toys make up a large proportion of the prizes available in Bandai Spirits’s crane games. We actively use stuffing material for our products made from 100% recycled, primarily from PET bottles. In fiscal 2024, we used recycled stuffing equivalent to approximately 38 million PET bottles for products won by customers.

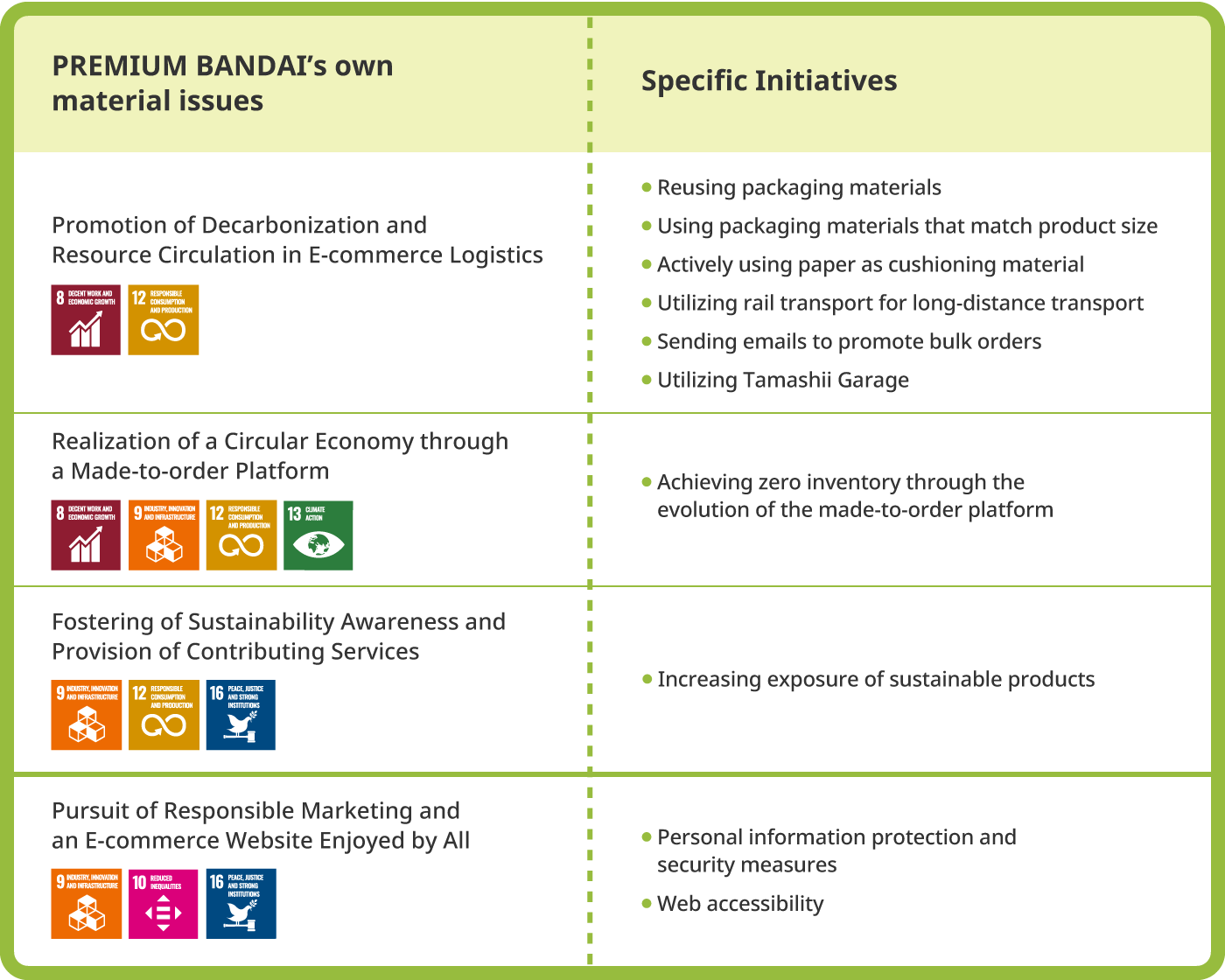

Premium Bandai E-Commerce Site contributing to a recycling-oriented society

Bandai Spirits operates the Premium Bandai e-commerce website, which sells limited edition Bandai Namco Group products as well as merchandise featuring characters from anime, comics, and more. Together with Bandai Logipal, which provides logistics services, we are working on sustainability issues based on Premium Bandai’s unique materiality. For example, with the aim of promoting carbon neutrality and resource recycling in e-commerce logistics, we are promoting the reuse of packaging materials. By establishing a built-to-order platform, we have achieved zero inventory, leading to reduced waste. We will continue to contribute to a recycling-oriented society, aiming to create an e-commerce site that can be enjoyed by a wide range of customers.